Jiuwei Joins Hands with Gree to Build Intelligent Warehousing Logistics

With the trend of global warming intensified, China's annual average temperature is getting higher and higher. It peaked in 2016 and 2021, with an average temperature of 10.5 degrees Celsius, and an average temperature of 10.5 degrees Celsius in 2021, an increase of 2.44 percent over the same period in 2020. According to data released by authoritative organizations, Gree's global market share of home air conditioners reached 20.2 percent in 2021, and brand retail sales once again topped the world's first. In the face of the growing market demand, Gree in order to improve the coordination of production and operation, to achieve intelligent warehouse, unmanned operation of the Hongye far map. Beijing Jiuwei Technology Co., Ltd. has joined hands with Gree to create an efficient, convenient and intelligent warehousing and logistics system, realizing the intelligent operation of Gree warehouse.

Customer Introduction

Zhuhai Gree Electric Appliance Co., Ltd. was established in 1991 and listed on the Shenzhen Stock Exchange in November 1996. In the early days of its establishment, the company mainly relied on assembly and production of household air conditioners, and has now developed into a diversified and technological global industrial manufacturing group, covering two major fields of household consumer goods and industrial equipment, and its products are exported to more than 180 countries and regions. The company has nearly 82000 employees, including nearly 16000 R & D personnel and more than 30000 technical workers. There are 77 production bases at home and abroad, as well as six renewable resource bases in Changsha, Zhengzhou, Shijiazhuang, Wuhu, Tianjin and Zhuhai, covering the whole industrial chain from upstream production to downstream recycling, realizing green, circular and sustainable development.

Project Overview

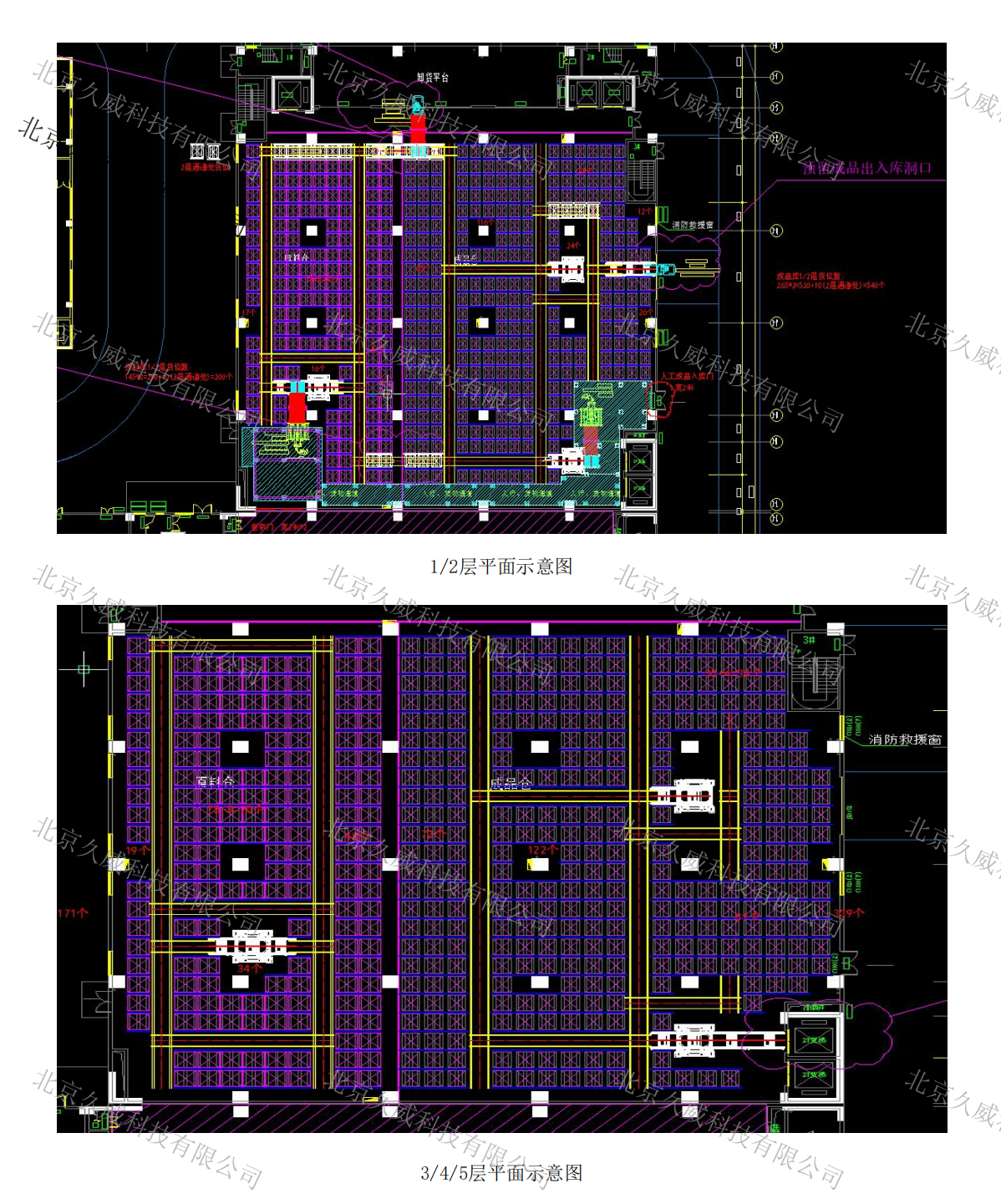

Zhuhai Gree project started construction in April 2022. The old warehouse is two small warehouses. The goods are stacked. The utilization rate of the warehouse is low and the work intensity of the warehouse staff is high. In order to reduce the work intensity of warehouse operators, improve warehouse operation capacity and strengthen production and operation coordination management, the customer plans to open up two small warehouses into a large warehouse and build an intelligent and modern three-dimensional warehouse. Beijing Jiuwei Technology Co., Ltd. undertook this project. According to the types of goods stored by customers, the quantity of daily incoming and outgoing goods, and the height and width of the warehouse, the scheme adopts software and hardware such as WMS and WCS of the four-way shuttle hoist conveying system for multi-layer dense shuttle shelves, and optimizes the design of regular storage operation links such as warehousing, delivery, inventory and tallying, thus realizing unmanned operation of intelligent warehouse for customers.

Project Programme

Dense shuttle shelf features

1. High density storage, high warehouse utilization.

2. High work efficiency, greatly reducing job waiting time.

3. The operation mode is flexible, and the access mode of goods can be first-in-first-out or first-in-first-out.

4. High safety factor, reduce the collision between the shelf and the forklift, and improve the safety productivity.

The lighting requirements are relatively low, compared with other types of shelves, the overall investment is less.

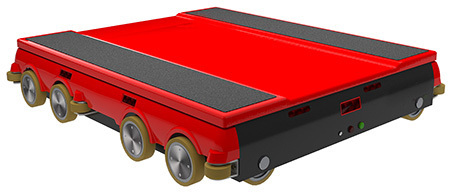

Four-way shuttle features

1. The height and size are small, which can save more storage space;

2. You can achieve four directions of travel on the supporting rack rails, and you can also use the vertical lift to achieve floor-changing operations, which further increases the layout of the warehouse shelves and the flexibility and scalability of the four-way shuttle car working in the warehouse;

3. It can travel along the vertical or horizontal track on the cross track of the three-dimensional shelf to realize one-stop point-to-point transportation, and can reach any cargo space on the warehouse plane layer. With the upper and lower elevators, the shuttle car can realize the efficient working mode of automatic and accurate floor change;

4. Realize three-dimensional movement of space and accurately control the entry and exit of each cargo space in the shelf area;

5. It has two working modes: automatic and semi-automatic. Greatly improve the efficiency of goods access and warehouse space utilization, but also can maintain the first-in-first-out storage of goods, to eliminate the confusion or inefficient operation of human factors;

6. Can make the goods in the warehouse according to the need to automatically out of the warehouse, greatly reducing the workload of warehouse personnel. Moreover, it can be organically connected with the production links outside the warehouse to facilitate the formation of an advanced logistics system and improve the level of enterprise management.

Hoist features

1. Steady lifting

2. Strong load capacity

Project Advantages

1. The original warehouse is two small warehouses, and there are no rules for the scattered stacking of goods, and the utilization rate of the warehouse is low. After the upgrade, the warehouse goods are placed in an orderly manner, which greatly improves the utilization rate of the warehouse.

2. The warehouse has basically realized intelligent operation, effectively reducing the work intensity of warehouse operators.

Latest recommend

Contact Us

Headquarters Address: 1801, Floor 18, Building 6, Jiayue Plaza, Yard 9, Hongye Road, Daxing District, Beijing

Hotline:139-1033-6413

Contact E-mail:lixiulan@jwrack.com

Get in touch with our team in time and be happy to help you