Jiuwei Technology Empowers Luzhou Laojiao to Build Intelligent Logistics Warehousing

With the rapid development of China's domestic liquor industry in recent years, the annual output value of liquor industry is increasing year by year. According to data from the National Bureau of Statistics, in 2021, enterprises above designated size in China's liquor industry (that is, annual output value of more than 20 million yuan) completed sales revenue of 603.348 billion yuan, an increase of 19.709 billion yuan from 583.639 billion yuan in 2020, an increase of 3.38 percent year-on-year. The total profit realized in 2021 was 170.194 billion billion yuan, an increase of 11.653 billion yuan from 158.541 billion yuan in 2020 and an increase of 7.35 year-on-year. At the same time, the rapid development of China's liquor industry also puts forward higher requirements for the logistics industry. The improvement of storage facilities and modern logistics management have become important factors to promote the development of liquor industry. Modern three-dimensional storage is also playing an increasingly important role in the storage management activities of the liquor industry.

Recently, Beijing Jiuwei Technology Co., Ltd. has joined hands with Sichuan Luzhou Laojiao to create an automated and intelligent storage system to realize the intelligent operation of liquor storage. Through the intelligent operation of the modern storage system, it makes full use of the existing storage resources, effectively uses the storage space, speeds up the construction of storage automation and information technology, improves the efficiency of storage operations, reduces logistics costs, and reduces the customer's demand for manual labor.

Customer Introduction

Luzhou Laojiao Group Co., Ltd. was established in December 2000. It is a wholly-owned state-owned enterprise, a well-known enterprise in China and one of the top 500 enterprises in China. The first enterprise to implement the joint-stock system in the national liquor industry is also the first liquor listed enterprise on the Shenzhen Stock Exchange. Luzhou Laojiao is the founder of Luzhou fragrance culture, the maker of Luzhou fragrance standards and the shaper of Luzhou fragrance brand, known as the "originator of Luzhou fragrance". Since 2005, after more than 10 years of hard work, it has led the construction of the country's first professional, clustered, and full-industry chain park with an area of about 15 square kilometers and a revenue of 112 billion yuan-Luzhou Liquor Industry Park.

Project Overview

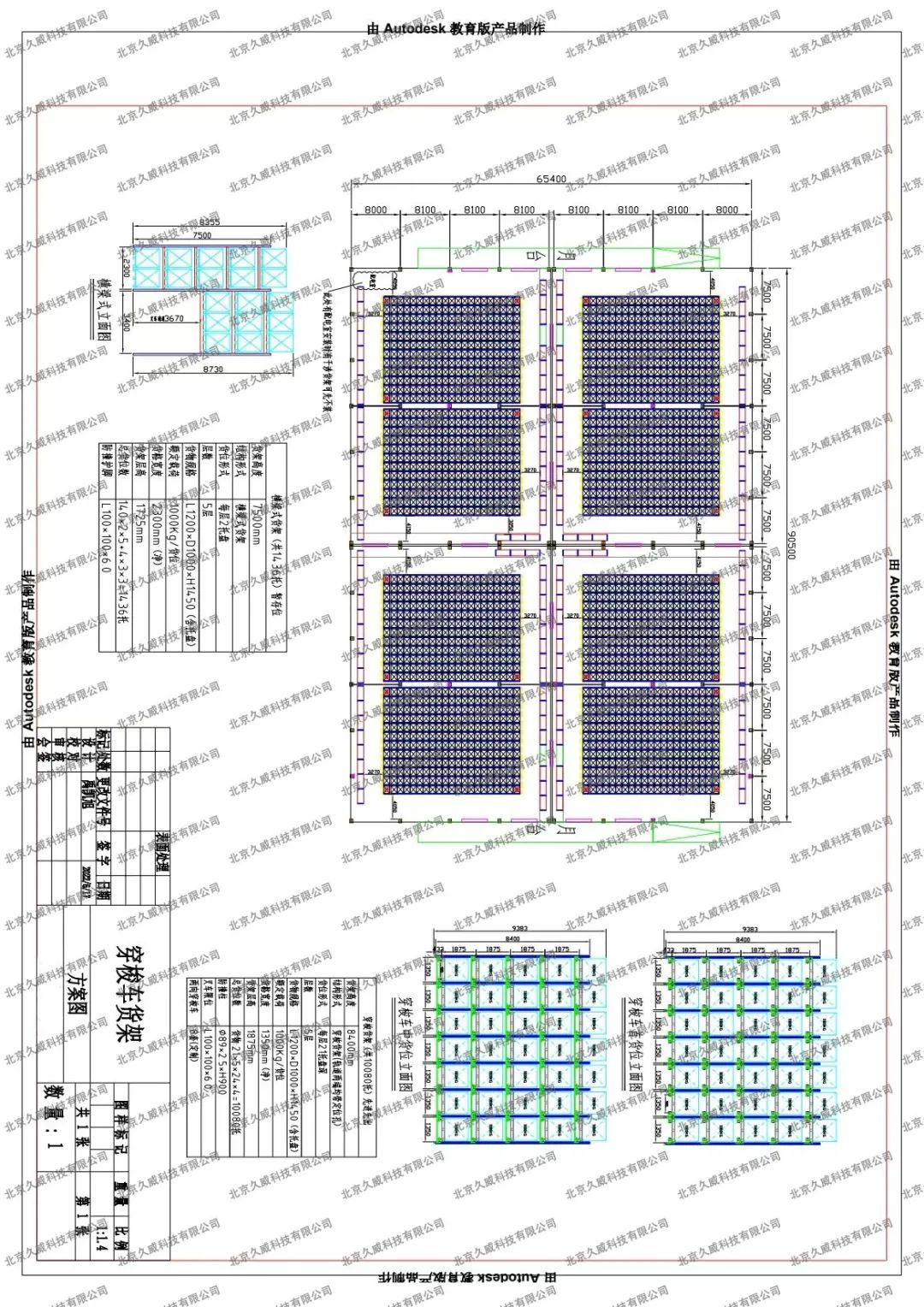

The Luzhou Laojiao Intensive Shuttle Project will start construction in October 2022,The warehouse is divided into 4 partitions, showing a "field shape", the east and west sides have a double platform structure, which can realize simultaneous warehousing and warehousing operations. According to the type of items stored by the customer, the quantity and efficiency of daily access and storage, and the height and size of the warehouse,The plan adopts intensive shuttle truck shelves, and the space utilization rate is increased by more than 80%,greatly fulfill the customer's storage needs,In terms of entering and leaving the warehouse, this project is equipped with 6 pallet shuttle trucks, which improves the work efficiency of forklift workers by 30%.Not only that, but also in the growth of the customer's later business by increasing the number of shuttle cars to meet the needs of work efficiency.

Difficulties in this construction

The project involves high reconstruction funds, long recovery period, obsolete ground conditions and line fire fighting facilities, and long reconstruction operation time. The construction difficulties involved are as follows:

1. The renovation of fire-fighting facilities shall meet the operation standard of Class C and Class II three-dimensional warehouse. The renovation of shelf design shall be completed in cooperation with the renovation design of fire-fighting facilities. At the same time, there may be cross-operation.

2. The warehouse is rebuilt while the warehouse is in and out of the warehouse. There are certain operational risks. About 80000 products in the warehouse need to be temporarily stored.

Solution

1. The first time to send professional design to fully cooperate with the fire protection design transformation, speed up the design and construction progress, reasonably arrange the construction plan in advance, and complete the project construction with full speed and high quality.

2. Without affecting the normal operation, we will rebuild the warehouse and temporarily store the goods at the same time. We will solve the construction problem in this way:

① Gradual construction of small batches of monomer storehouse, and construction of 1/4 monomer storehouse first;

② The single warehouse shall be constructed in different areas, leaving a certain passage and assembly space;

③ Make reasonable use of the temporary storage position on the platform;

④ Speed up the construction progress, and the pre-assembly work should be completed in advance;

As long as the construction of the 2879 storage site (115160 pieces in total) of the first partition library is completed, this risk will be basically eliminated.

Scheme Layout

According to the height of the warehouse, the design of the three-dimensional warehouse is up to five floors, which is planned in combination with the lifting height of the existing forklift equipment and the product structure of the warehouse area:

Storage on the first floor:To store large-size heavy goods and promotional products, shorten the operation path, reduce the risk of operation;

2. three layer storage:Mainly to store bulk circulation products, product specifications standard, large amount of work, the existing low battery and three 5 meters in the middle of the electric forklift can work;

Four layer storage:To store semi-circulation products, high-level electric forklift operations, product planning for regional products, semi-stagnant goods;

Five layer storage:To long-term storage products, high-level electric forklift operation, product planning for unsalable, three-person dazzle series.

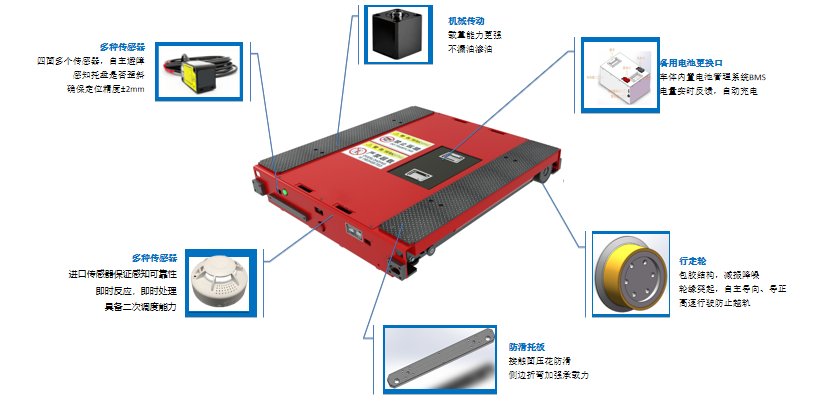

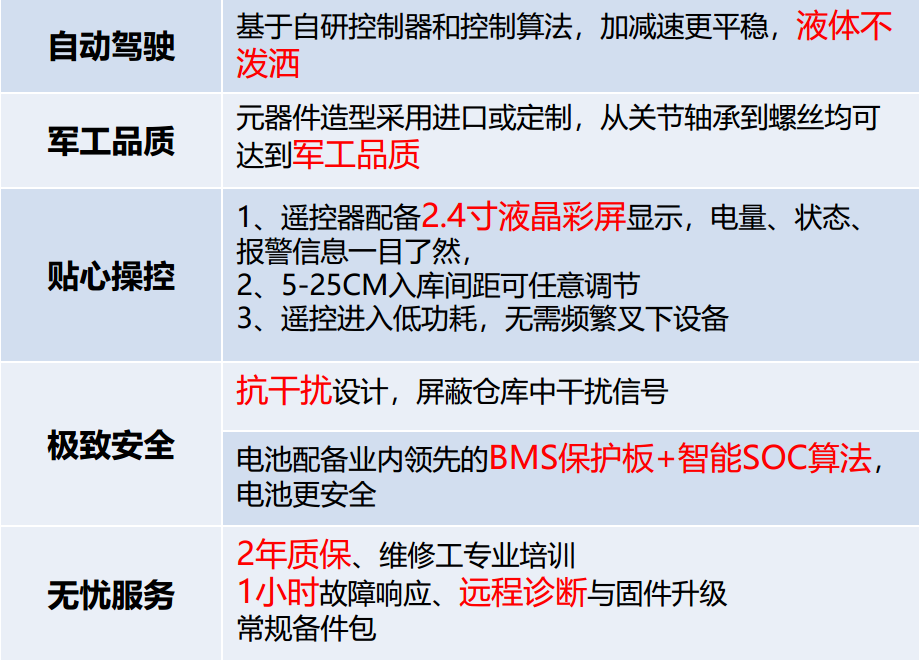

Shuttle car introduction-two-way car structure

Shuttle advantages

Dense Shuttle Rack Features

1. High density storage, high warehouse utilization.

2. High work efficiency, greatly reducing job waiting time.

3. The operation mode is flexible, and the access mode of goods can be first-in-first-out or first-in-first-out.

4. High safety factor, reduce the collision between the shelf and the forklift, and improve the safety productivity.

The lighting requirements are relatively low, compared with other types of shelves, the overall investment is less.

Project Advantages

1. The original warehouse is a flat warehouse with less stored goods. After upgrading, it can not only meet the storage of bulk categories, but also support the management of bulk or small-size categories. The double platform reserves a product stocking area so as to realize advance stocking during peak seasons, make full use of existing forklift equipment, reduce unnecessary purchase of fixed assets, and increase storage capacity by 100.

2. The operation method is flexible, which can be first-in, first-out, or first-in, which improves work efficiency and greatly reduces the amount of manual work.

Latest recommend

Contact Us

Headquarters Address: 1801, Floor 18, Building 6, Jiayue Plaza, Yard 9, Hongye Road, Daxing District, Beijing

Hotline:139-1033-6413

Contact E-mail:lixiulan@jwrack.com

Get in touch with our team in time and be happy to help you